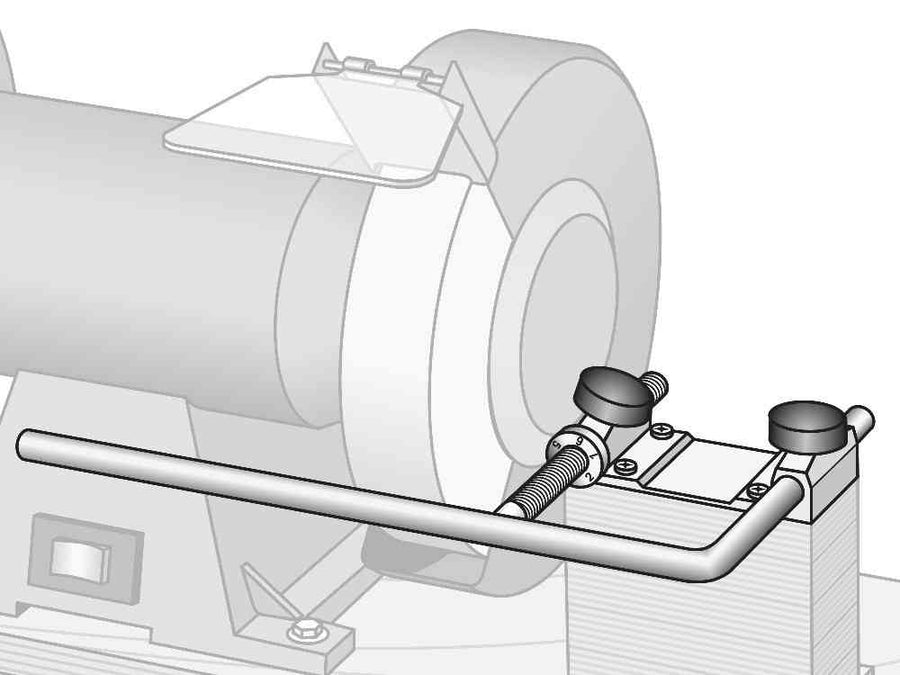

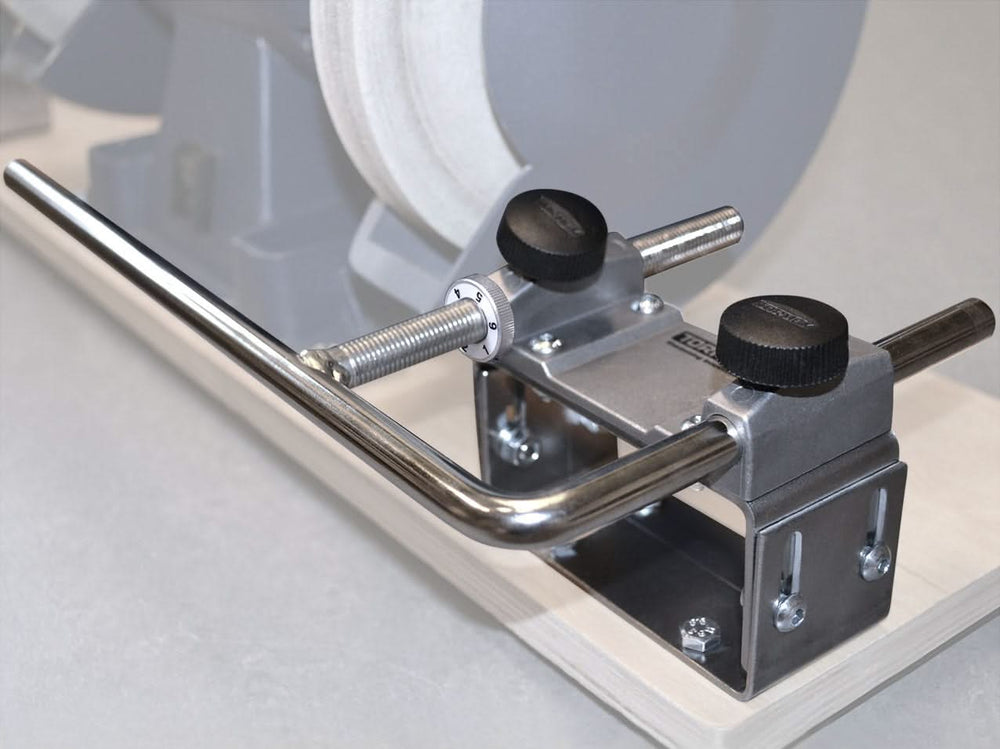

If you need to remove a large amount of steel to create a desired profile on a new tool, the BGM-100 bench grinder mounting kit allows you to use Tormek wood turning devices on your bench grinder as well.

Take control of your profiles

No matter what grinding machine you use, the hardest part of sharpening woodturning tools is replicating the exact profile and angle of the cutting edge.

With the BGM-100 you can now use the following Tormek devices on your bench grinder: the SVD-186 gouge device, the SVS-50 Multi device, the SVD-110 sharpening stand and finally, but not least of all, the TTS-100 turning tool positioner.

What does the BGM-100 kit contain?

This kit contains an adjustable height block, hardware, a universal stand, a horizontal base and legs for the base you will be building, along with full instructions. Attach the kit to one side of the grinding wheel.

Why also offer Tormek devices for bench grinders?

We think Tormek's water system is the best for sharpening virtually any edge tool in your shop. It's no secret, however: when it comes to woodturning tools and you need to remove a lot of steel, initial shaping can be done faster with a bench grinder. We know that many turners have a bench grinder and use it for the first rough shaping.

If you have a Tormek sharpening machine

With the BGM-100 you can use the same Tormek precision devices throughout the entire sharpening process. There is no longer a trial and error process to get the right profile on the bench grinder. With the TTS-100 positioner, you can take advantage of high-speed steel removal from the bench grinder, and without changing the settings, switch the tool to the Tormek water grinder and leather honing disc to achieve the finish and the fineness of final edge.

If you don't have a Tormek sharpening machine

If you don't already have a Tormek machine, you can still take advantage of the Tormek precision fixture system to get the profile and edge angle you want on your bench grinder. The principle for adjusting the profile and edge angle is the same regardless of the machine you are using. If you then choose to add a Tormek machine to your workshop, you will already have the necessary devices for the turning tools.

About bench grinders

Use the right grinding wheel

All grinding wheels are suitable for precise sharpening of cutting tools. Standard factory-fitted grinding wheels, often too hard, clog and ice easily, which limits their efficiency and causes the tool to overheat. Dull grits must wear down or peel off to reveal the next ones. Otherwise, they rub the steel instead of lapping it, creating friction and overheating. Choose an aluminum oxide wheel with the right bond – not too hard to avoid glazing and not too soft to avoid chasing.

grinding wheel surface

The grinding wheel surface should be kept clean and straight. Maintain it regularly with a diamond dressing tool.

The effects of overheating on HSS high speed steel

HSS high speed steel can withstand much higher temperatures than carbon steel. However, at the very thin end of the cutting edge, the temperature can easily reach a level affecting the hardness. Therefore, grind the end carefully and do not let it turn blue. Overheating HSS can decrease hardness by at least 4 HRC and reduce edge life. If you cool it in water, do not do it suddenly from a high temperature because this can create micro cracks invisible to the naked eye.

grinding dust

The fine dust resulting from the grinding wheel and the steel particles is hazardous to health. It is better to use a suction device to channel the dust. Use a vacuum cleaner other than the one intended for wood shavings and sawdust because the slightest spark could create a fire in the fine and flammable dust.